March 9, 2023

Technicians are hard at work installing three new electric injection molding presses at Cadrex’s state-of-the-art sheet metal fabrication facility in Monterrey, Mexico. The addition combines sheet metal fabrication and injection molding capabilities in one facility — which is new for Cadrex and a rarity in the industry. This is a big step in Cadrex’s history, which has over 50 years of experience in injection molding.

The new machines will be fully operational by mid-April. Our facility in Westminster, Colorado currently has 130,000-square-feet of injection molding space with 33 injection molding presses ranging in tonnage from 28 to 720. Customer support for tool design and design for manufacturability (DFM) engineering will continue to be led by our team out of the Colorado plant.

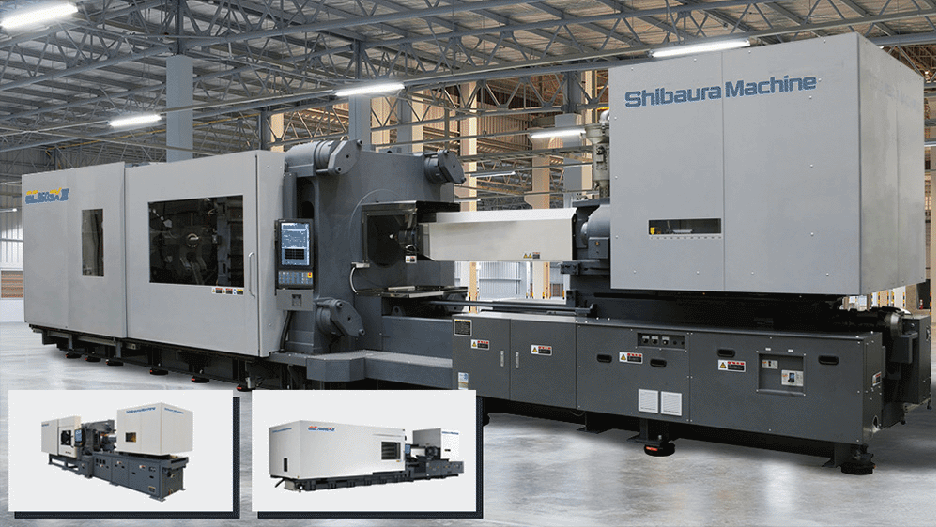

New Injection Molding Presses

The new electric injection molding presses range in tonnage from 390 to 950 and can support medium- to high-volume programs. The machines have smart digital systems, and they can analyze part defects, troubleshoot problems, and integrate with auxiliary equipment. They deliver fast injection speeds and dry cycle times, ensure longer mold life, and allow for greater productivity, flexibility, and versatility.

We will continue ramping up capacity and expanding our capabilities at the Cadrex facility in Monterrey. Our expansion into Mexico provides manufacturing for customers with in-region requirements, plastic components required in current sheet metal programs, and overmolded metal and plastic products.

Recent Insights

News

Blog

White Papers